- Contact

- |

- Data protection

- |

- Imprint

- |

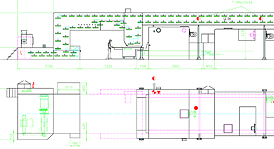

As a comprehensive project management, we understand with the Beta Bakery Engineering a projects being executed that is for our customers purposeful, smooth, on a minimum-cost level and punctual. Just in the beginnings of a new project, with the decision that new production capacities must be accomplished, you set the course for later productivity, accomplishment and quality of the bred product. Deviations at the further course of the project are reduced by a specific consulting and exact definition of the needs. By a consequent project control, the pitched milestones of the project are satisfied. Variances of all kind are recognised early and countermeasures are initiated.

At the outset of every project, the demand and capacity planning is determined to notice exactly in which line capacities it has to be invested. Hence a product requirement document is developed which serves on the other hand as a basis for the choice of the capital goods. The product requirement document also contains the budget plan besides the technical details.

When the need and the wanted line version are known, you get a professional project plan which is customized and perfectly adapted for your needs. The plan contains besides the components all actions brought into the necessary level of detail - with milestones and the description of the critical path.

With the prepared documents the choice of the components as well as the supplier selection is made. After price negotiations having been carried out, binding contracts with the suppliers are contracted. Delivery dates which are exact and coordinated with each other are arranged and fixed in writing in accordance with the prepared project plan.

By these measures we can guarantee a frictionless assembly which we like to conduct and to supervise by request.

The site acceptance test (SAT) follows the putting into operation and the test production. Here the completeness and demanded quality are again checked strictly after the product requirement document (PRD).

The Beta Bakery Engineering organizes for you complete removals of used large lines. We deal the removal beginning with the planning up to the putting into operation. We supply the required assembly team. By request, we work out a concept for an overhaul of the line as well as for partial renewals, such as control engineering, mechanical units etc.